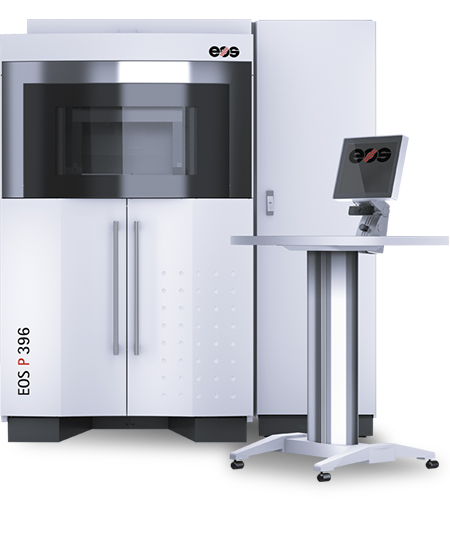

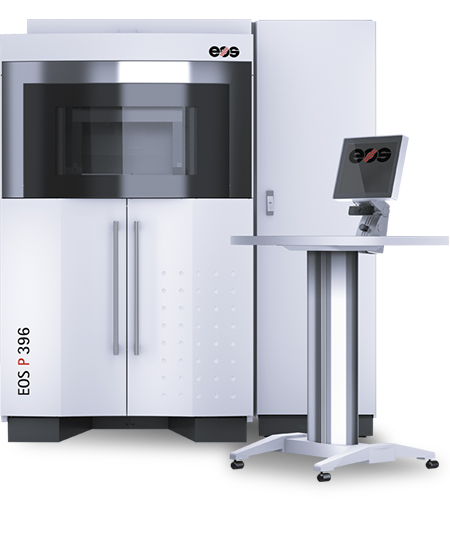

EOS P396

- work chamber: 340 mm x 340 mm x 600 mm

- building speed: up to 48 mm/h

- layer thickness: 0.12 mm - 0.15 mm

Rapid prototyping is a set of technologies of prototype implementation with the help of 3D printing.

We deal with it in our department of additive production in Mladá Boleslav. We devote our time there mainly to prototype and small series production which meets the requirements of prototype workshops and design studios to which we offer through our work a base for judging design and engineering.

Based on our customer’s wish, the components also go through finishing operations (varnishing, sanding, metallizing, polishing etc.) or they are used as master models for vacuum casting.

Assembly of elaborate systems of parts. Technology combination, SLS, casting, varnishing, metallization. Precise finishing.

Metallization of parts according to customer’s instructions. Variation of different surface types.

Difficult finished parts during optical parts‘ manufacturing.

Manufactured with SLS technology. The model underwent trial test right in motor space after finishing works and resin application.

Visualization of work progress in prototype manufacturing. Engineering, finishing, completion, casting with customer’s parts. Technology combination according to its usability.

A fully functioning headlight model.

We are here for you and we are looking forward to new challenges! If you have any questions, write right here or use our direct contacts